What We Do

Services

Consulting

With many years of experience in the manufacturing arena, Molded Marketing is ready to provide:

- Manufacturing Consulting Services

- Injection Molding Consulting Services

- Total Program Management

- Off-Shore Business Practice Advisory

- Expert Witness Testimony

Our clients have come to rely on our team for expert guidance in all areas of their business. From a single mold to a full turn-key manufacturing site, Molded Marketing provides it all.

Mold Making

Molds come in all shapes and sizes. From “Micro-Molds” with shot weights of a few grams to conventional molds with part weights of 10 pounds or more, we have experienced tool design engineers and mold makers to meet your needs.

Our mold making partners around the globe have RJG™ certified Master Molders on staff. The highly trained members of our team are here to provide the guidance needed when designing and then processing new tooling.

Our goal is to ensure that our customer partners receive all of the needed support to hit the ground running on receipt of a new mold from Molded Marketing LLC.

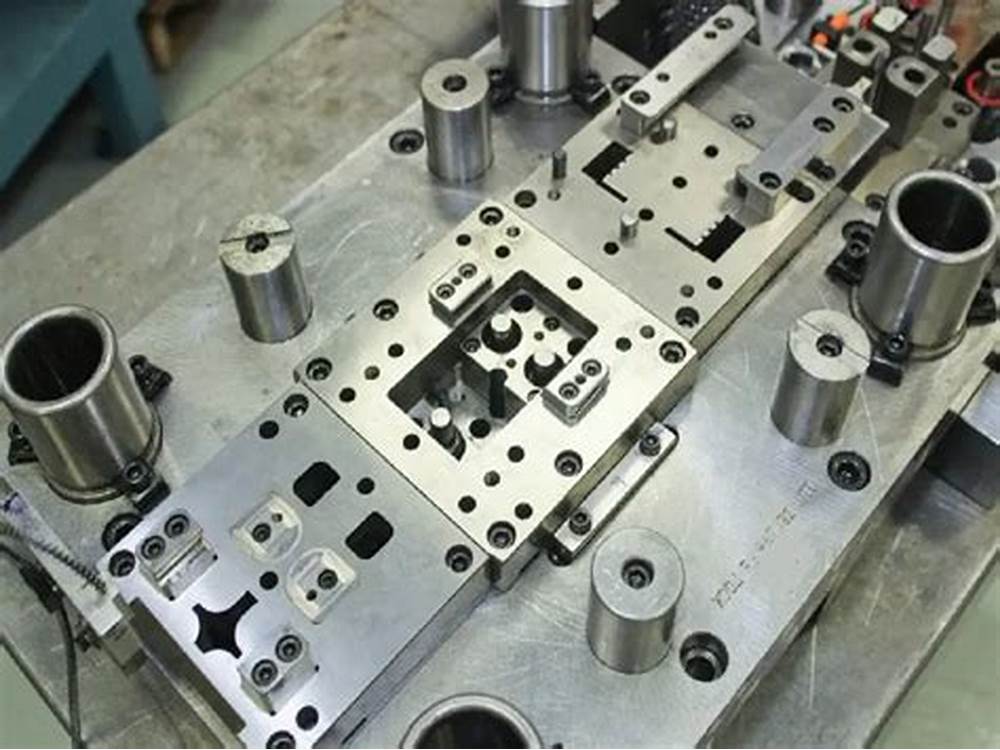

Die Making

Whether a simple semi-automatic work station or a full on assembly cell, Molded Marketing’s team of experts stands ready to meet your needs.

Our Process Engineers stand ready to meet your most exacting needs for automation equipment. We don’t take a one size fits all approach. Instead we listen to your team to find the critical points related to your project. Then we commit those points to a project Bid Specification that outlines the expected through-put, machine components and any other specifics to your program.

With over 50 International Patents for Automation Applications, we provide:

- Machines designed and built to your specifications; including SCARA, 4-Axis, 6-Axis Robotic Integration and Full Q/A Reporting and Vision System Integration.

- Weekly Project Status Reporting

- Pre-Shipment Machine Run-Off in our facilities

- Full Process Documentation, Full Design Documentation, Anticipated High-Wear Parts List, and Operations Manual in English.

- Remote machine/control diagnostics via web-protocol

Assembly Automation

Stamping dies, much like injection molds, also come in varying types. Our skilled Die Designers and Die Makers are ready to handle your project. Whether you need a Single Hit Semi-Auto Transfer Die, or a Highly Complicated Progressive Die, or a Deep Draw Forming Die, Molded Marketing LLC has the right solution for you.

We have experience in High Speed Continuous Strip Dies providing inserts for encapsulation molding in fine metals.

Fine Blanking Dies, our “Can-Do Die Makers” will provide the tooling that is needed On-Time — Every Time.

Die materials including Standard Die Shoes, High Carbide D-2, Hot Working H-13, Shock Working S-7, Self-Lube O-1 or O-6. are employed in the right places on all projects.

We have the experience to provide the right combination of tool steels for a long life tooling solution.

Product Realization

When our clients reach out with a new product concept, our team is at the ready. We listen closely to fully understand the goals of the product... The marketplace... The functional high points... Target production costing... And of course the Product Launch Date.

With that information in hand, we prepare a Project Plan. We evaluate the concept in “DFM” (Design For Manufacturing) review and help to value engineer the product from the start.

Some projects require hand made models for photo shoots and trade shows. We have that covered.

Some require demonstration samples of 5—10 parts for review with investors and potential customers. Our team has resources to meet those needs as well.

Other projects are more advanced and there is a desire to have manufactured samples from the planned process for fit/function evaluation.

Molded Marketing has the right resources to take your product from a compelling idea all the way to commercially available items while adhering to your timing requirements.

Our Sourcing Checklist

When considering a new supply partner with the capabilities offered at Molded Marketing, we believe a quick checklist is a crucial tool. So here is ours to aid in making your selection:

- Design for Manufacture Review

- CAE Services including Mold Flow/Fill

- Injection Molding Services

- Plastic Extrusion Services

- Stamped and Deep Drawn Metal Parts Manufacturing

- Zinc Die Casting Services

- Swiss Turn and Screw Machine Services

- CNC Machining Services

- Rapid Prototyping—Molded Parts

- Rapid Prototyping—Model Making

- Injection Mold and Die Cast Die Making

- Progressive Stamping Die Making

- Factory/Assembly Automation

We have the experience to provide the right combination of resources to achieve the best overall solution in a timely manner.

What We Do

Project Launch to Delivery

Kick Off

On receipt of an order to proceed, we complete our detailed DFM Review. Looking at the full project we consider initial tooling, production capability and finally tooling maintenance. We know that every project must meet all stakeholder requirements to be considered a success.

Program Progress

We keep you informed of all progress through weekly reporting. The reports include photos of the work (where possible) and any adjustments to the time line... Good news is always pleasant to receive, but sometimes bad news must be digested as well... And we all know that ‘Bad News Doesn’t Improve With Age.’

Pre-shipment Trials

With very few exceptions, we perform extensive pre-shipment trials. The deliverables include: - Process Setting Documents - T-1 Pre-shipment Part Inspections - In-Process Video - Full Design Documentation

Delivery

Our job isn’t finished until you and your product are in full production. We are there to provide support during start-up and Production Commissioning. Truly an extension of your team.